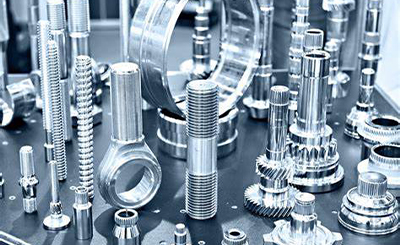

Rack Plating

In the rack plating method, parts are mounted on a rack, which is then dipped in the plating solution. The parts are secured using specially designed jigs.

Plating individual parts can be time-consuming and expensive. The rack plating method involves organizing the parts needing plating into a rack.

This method is particularly utilised for

if your parts are particularly fragile, complex or large.

- Examples:

- Large Auto components

- White Good Industry components, etc.

Salient Features of our Equipment:

- Modular Structures.

- Plate-type filtration systems.

- Water conservation techniques.

- Anode maintenance platform for safe anode filling.

- Techniques to prevent inter-tank contamination.

- Scrubbers using Munters PVC profiles for Drop Separation.

Best in class Plant Management System:

- Monitor and manage parameters such as:

- Temperature

- Current/Ampere

- Immersion times and also the part code entry into the individual process tanks

- Auto Dosing

- Chemical Maintenance

- Additional features include:

- The interactive screen helps the operator in entering parameters with ease.

- Alarm/Alert for all the predefined parameters, and visual representation of the same with predefined colour codes.

- Real-time DATA collection and control.

- Multi-user level access using password a tamper-proof system.

- Mimic screen displaying transporter status, part No., lot No., etc.