Where Customer Delight is just the beginning……….

Kamtress derives its strength of offerings from its service set up. The unflinching commitment to supporting customers throughout the lifecycle of projects pre and post installation have guided us in setting up a dedicated Service team.

The Service team works with a single minded objective of ensuring business continuity for our customers by focussing on achieving highest plant availability. We work around the clock to plan, prepare, forecast and address any exigencies so that our customers can focus on their core business.

Spares

Modernisation & Modification

Maintenance

Training

Spares

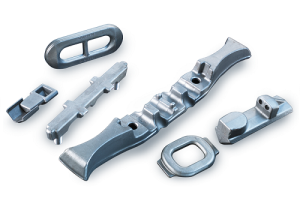

We understand that projects need to be supported by long term availability and supply of spare parts. At Kamtress, our focus is on ensuring that customers have a seamless experience when it comes to ordering capital spares or consumables.

We are centred around ensuring availability of spares that are compatible with your existing plant along with the optimal safety standards and are always on time irrespective of your location.

From filter tubes and baskets to pumps, rectifiers, tanks and anodes, Kamtress provides all supplies you’ll need to run your operation smoothly and efficiently.

Some commonly ordered typical wear parts in a chemical surface treatment plant include

- Electric Heaters

- Transporter Wheels

- Lifting Belts

- Pumping Accessories

- Current Forks

Electric Heaters

Transporter Wheels

Lifting Belts

Pumping Accessories

Current Forks

Sample Capital Spares

- Tanks

- Barrels

- Flight Bars

- Transport Wagons

Tanks

Barrels

Flight Bars

Transport Wagons

Corrosion Protection

Wear Resistance

Modifying Electrical Conductivity

Improved Adhesion

Friction Modification

Aesthetics

We specialise in designing and manufacturing NADCAP-approved surface finishing plants for a range of chemical processes:

Anodizing

Hard Chrome Plating

Zinc/Nickel Plating

Cadmium Plating

Electroless Nickel Plating

Passivation

Modernisation & Modification(M&M)

The rapidly changing and evolving industrial scenario requires customers and equipment suppliers to be “ready” to offer state of art solutions in synchronisation with the modern times & requirements of the customer.

Kamtress provides consulting support and executes modernization projects, focussed at upgrading your current plant and automation system.

The key steps involved in M&M Services are

- Understanding Customer Objectives.

- Site Visit for Technical Evaluation.

- Customer Discussions to benchmark key objectives/deliverables.

- Agreement & Finalisation of Scope

- Commercial Discussions and Contract Sign Off.

- Execution of Commitments.

Corrosion Protection

Wear Resistance

Modifying Electrical Conductivity

Improved Adhesion

Friction Modification

Aesthetics

Common applications of anodizing include:

Components from the Aerospace Industry.

Architectural equipments like, Roofs, Window Frames, Ceilings, exterior components on buildings.

Computer hardware and household appliances.

We specialise in designing and manufacturing NADCAP-approved surface finishing plants for a range of chemical processes:

Anodizing

Hard Chrome Plating

Zinc/Nickel Plating

Cadmium Plating

Electroless Nickel Plating

Passivation

Maintainance & Training

Kamtress offers customised maintenance programmes for chemical surface finishing plant users. We are focussed on providing a diverse set of maintenance modules aimed at minimising your maintenance tasks and costs.

Talk to us to know more about our Preventive and Predictive maintenance programmes.

Training

In addition to the maintenance contracts, Kamtress frequently organises paid training programmes for its patrons to keep them updated on “Best Operations & Maintenance Practises” in addition to discussing & sharing specific experiences/case studies encountered and the trouble shooting mechanisms adopted.

These programmes help our patrons steepen their learning curve and provide for a “real time” interactive platform for exchange of ideas between the end users and the plant designers.

Training Programmes could be custom built as per customer needs and objectives.

Feel free to connect with us to learn more

Corrosion Protection

Wear Resistance

Modifying Electrical Conductivity

Improved Adhesion

Friction Modification

Aesthetics

Common applications of anodizing include:

Components from the Aerospace Industry.

Architectural equipments like, Roofs, Window Frames, Ceilings, exterior components on buildings.

Computer hardware and household appliances.

We specialise in designing and manufacturing NADCAP-approved surface finishing plants for a range of chemical processes:

Anodizing

Hard Chrome Plating

Zinc/Nickel Plating

Cadmium Plating

Electroless Nickel Plating

Passivation

Corrosion Protection

Wear Resistance

Modifying Electrical Conductivity

Improved Adhesion

Friction Modification

Aesthetics

We specialise in designing and manufacturing NADCAP-approved surface finishing plants for a range of chemical processes:

Anodizing

Hard Chrome Plating

Zinc/Nickel Plating

Cadmium Plating

Electroless Nickel Plating

Passivation