Aerospace Industry

Surface Finishing is exceptionally critical when it comes to the aerospace industry. Surface Finishing in the aerospace industry is done primarily to solve the following issues:

Corrosion Protection

Wear Resistance

Modifying Electrical Conductivity

Improved Adhesion

Friction Modification

Aesthetics

- Corrosion Protection

- Wear Resistance

- Modifying Electrical Conductivity

- Improved Adhesion

- Friction Modification

- Aesthetics

Several components and systems require surface finishing in the Aerospace industry. Some notable components and systems are mentioned below:

Landing Gears

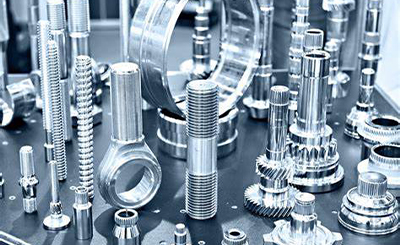

Engine Components

Navigation Systems

Helicopter Rotor Blades

Electrical Hardware

Typical chemical processes for aerospace components:

Anodizing

Hard Chrome Plating

Zinc/Nickel Plating

Cadmium Plating

Electroless Nickel Plating

Passivation

We specialise in designing and manufacturing NADCAP-approved surface finishing plants for a range of chemical processes:

Anodizing

Hard Chrome Plating

Zinc/Nickel Plating

Cadmium Plating

Electroless Nickel Plating

Passivation

Types of Plants

Rack Plant

Types of Plants

Barrel Plant

Types of Plants

Rack-Barrel Combination