Electrical Industry

One of the most important processes in the manufacturing of electrical and electronic parts and components is electroplating, which involves the application of a metal coating via electrodeposition. The primary reasons for electroplating electronic components are:

Corrosion Protection

Wear Resistance

Modifying Electrical Conductivity

Improved Adhesion

Friction Modification

Aesthetics

- Corrosion Protection

- Enhancing Electrical Conductivity

- Increasing Solderability

- Wear Resistance

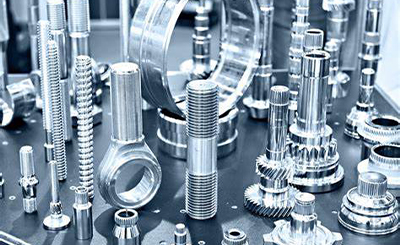

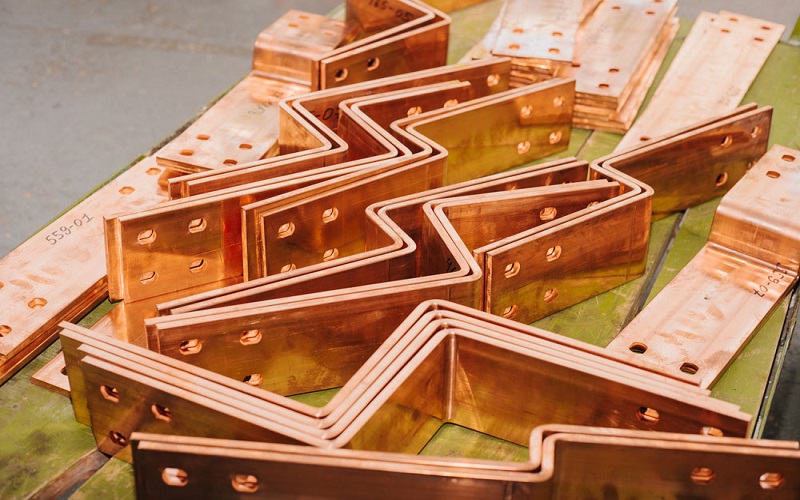

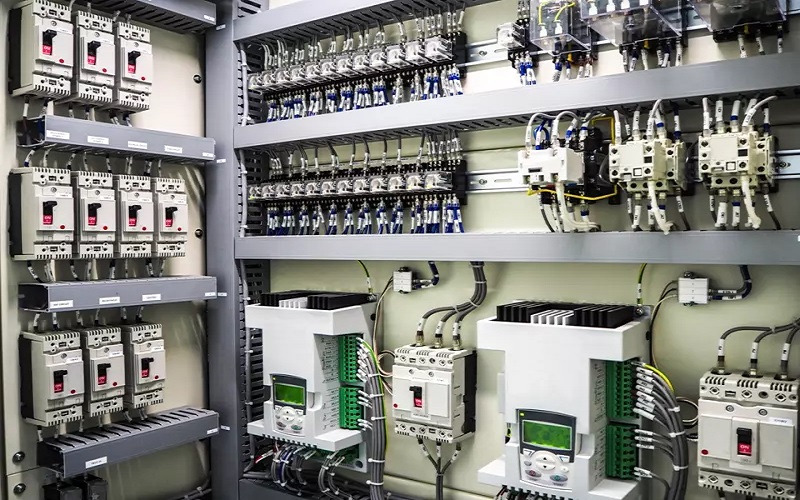

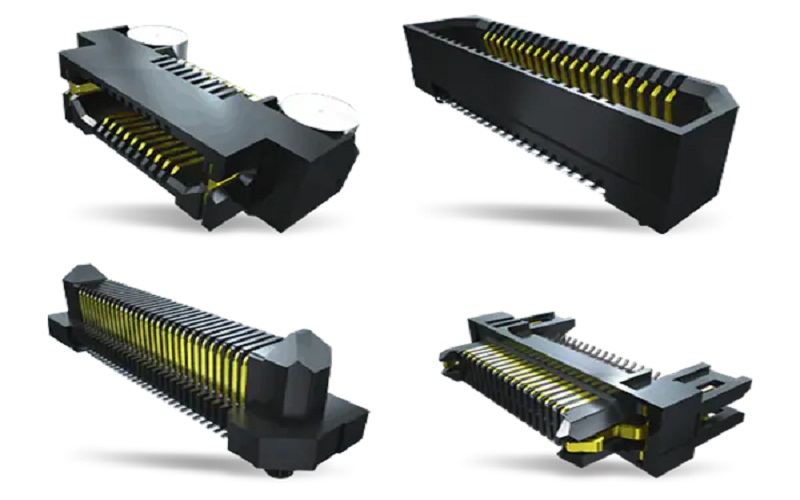

Components that usually require surface finishing include:

Switch Gears

Electrical Connectors

Electrical Busbars

Electrical Contacts

Typical chemical processes for electrical components:

Gold Plating

Silver Plating

Copper Plating

Tin and Tin Alloy Plating

We specialise in designing and manufacturing NADCAP-approved surface finishing plants for a range of chemical processes:

Anodizing

Hard Chrome Plating

Zinc/Nickel Plating

Cadmium Plating

Electroless Nickel Plating

Passivation

Types of Plants

Rack Plant

Types of Plants

Barrel Plant

Types of Plants

Rack-Barrel Combination