Anodizing

Anodizing is an electrochemical process to convert the metal surface into an anodic oxide finish that is durable and highly corrosion resistant. The anodic oxide structure originates from the aluminum and is composed entirely of aluminum oxide, in the simplest terms the aluminum oxide is grown from the underlying aluminum substrate. Anodizing is extensively used in the Aerospace Industry to make aluminum components durable and corrosion resistant.

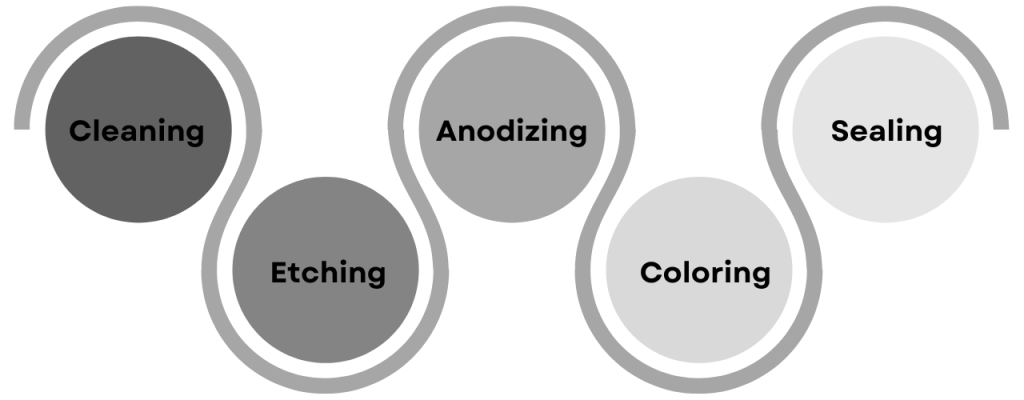

The anodizing process consists of five broad steps:

Benefits of Anodizing:

Corrosion Protection

Wear Resistance

Modifying Electrical Conductivity

Improved Adhesion

Friction Modification

Aesthetics

- Corrosion Resistance

- Wear and Tear resistance

- Aesthetic finish with a range of colors available

Types of Anodizing:

Chromic Anodizing

Aluminum Anodizing

Hard Coat Anodizing

Common applications of anodizing include:

Components from the Aerospace Industry.

Architectural equipments like, Roofs, Window Frames, Ceilings, exterior components on buildings.

Computer hardware and household appliances.

We specialise in designing and manufacturing NADCAP-approved surface finishing plants for a range of chemical processes:

Anodizing

Hard Chrome Plating

Zinc/Nickel Plating

Cadmium Plating

Electroless Nickel Plating

Passivation

Types of Plants

Rack Plant

Types of Plants

Barrel Plant

Types of Plants

Rack-Barrel Combination