Automotive Industry

Vehicles today are subjected to extreme environments, from increased city driving to taking them out in extreme weather conditions or less predictable terrain. These factors, together with increasing expectations, mean that individuals and companies are more demanding than ever before. This is especially the case when it comes to coatings, finishes and surfaces.

Surface Treatments in the Automotive industry are done for a variety of reasons such as:

Corrosion Protection

Wear Resistance

Modifying Electrical Conductivity

Improved Adhesion

Friction Modification

Aesthetics

- Corrosion Resistance

- Wear Resistance

- Improvement of Aesthetics

- High-Temperature Resistance

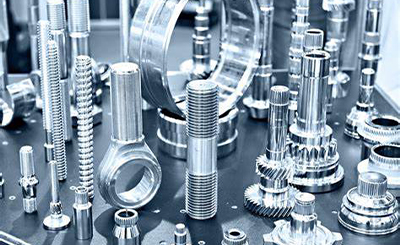

Surface finishing can be done on a variety of components:

Under-Hood Components

Power Steering Systems

Chassis Components

Braking Systems

Fasteners

Body Panels

Wheels/Rims

Bearings

Shock Absorbers

Typical chemical processes for automotive components:

Zinc and Zinc Alloy plating

Nickel Chrome plating

Plating on Plastics (POP) or ABS plating

Phosphating

Anodizing

We specialise in designing and manufacturing NADCAP-approved surface finishing plants for a range of chemical processes:

Anodizing

Hard Chrome Plating

Zinc/Nickel Plating

Cadmium Plating

Electroless Nickel Plating

Passivation

Types of Plants

Rack Plant

Types of Plants

Barrel Plant

Types of Plants

Rack-Barrel Combination