Barrel Plating

Barrel plating is a technique used for coating small parts in bulk quantities. This method involves using a barrel, which resembles a perforated industrial container, to obtain desired results.

In barrel plating, parts are placed in a perforated rotating barrel for uniform coating. The barrel is submerged in various chemical baths to achieve the desired outcome. This process results in ions in the electroplating solution to bond with the surface of the objects.

This method is particularly utilised

- For plating high volume of parts in a short time

- To handle an assortment of differently sized and shaped parts

- Examples:

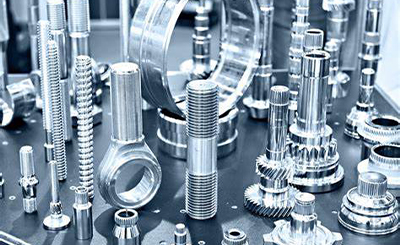

- Small, sturdy components like fasteners and hardware

Salient Features of our Equipment:

- Modular Structures.

- Plate-type filtration systems.

- Water conservation techniques.

- Anode maintenance platform for safe anode filling.

- Techniques to prevent inter-tank contamination.

- Scrubbers using Munters PVC profiles for Drop Separation.

Best in class Plant Management System:

- Monitor and manage parameters such as:

- Temperature

- Current/Ampere

- Immersion times and also the part code entry into the individual process tanks

- Auto Dosing

- Chemical Maintenance

- Additional features include:

- The interactive screen helps the operator in entering parameters with ease.

- Alarm/Alert for all the predefined parameters, and visual representation of the same with predefined colour codes.

- Real-time DATA collection and control.

- Multi-user level access using password a tamper-proof system.

- Mimic screen displaying transporter status, part No., lot No., etc.