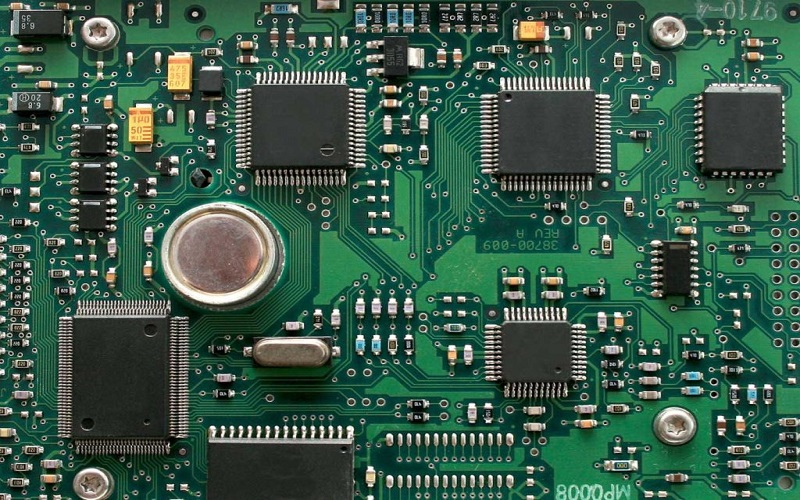

Printed Circuit Board

Plating on a Printed Circuit Board (PCB) refers to the electrochemical process by which a metal is deposited onto the surface of the circuit board, and inside the plated through-holes. Copper is the most frequently used metal for PCB plating.

Corrosion Protection

Wear Resistance

Modifying Electrical Conductivity

Improved Adhesion

Friction Modification

Aesthetics

- Lower Contact Resistance

- Protection from Oxidation, Moisture & Contamination

- High Wear Resistance

- Electricity Conductivity

Types of Process

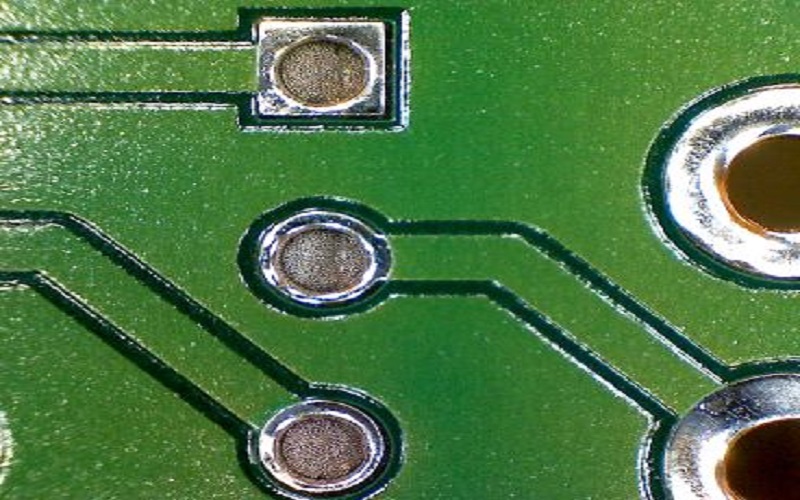

PTH (Plating Through Hole)

Copper Tin Pattern Plating

Electroless Nickel Immersion Gold

Etching

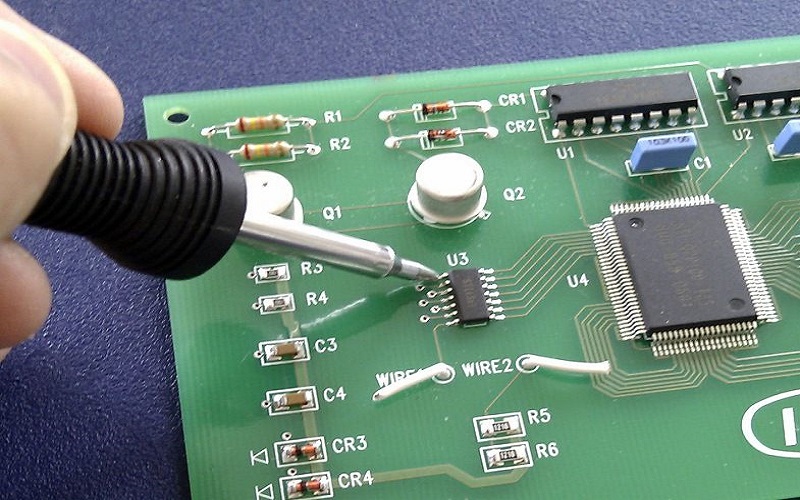

PCB manufacturing process includes etching a copper sheet plated onto a non-conductive substrate and drilling holes through it. These holes will be conductive after the plating process (electroless copper deposition), which will form a thin layer of copper on the walls of the hole.

Typical chemical processes for printed circuit board components:

Alkaline Degreasing

Remove oil, fingerprints, oxides, dust etc. on the surface of the board.

Microetching

Eliminate the oxide layer on the board's surface and roughen it to enhance the adherence between the upcoming copper layer and the substrate's underlying copper.

Preimpregnation

It is mainly done to protect the palladium slot from being polluted from the bath of pre-treatment and extend the shelf life.

Activation

Activation plays a crucial role in determining the quality of the following copper plating.

Desmearing

Eliminate the stannous ion surrounding the palladium particle in the colloid to uncover the palladium core, allowing it to effectively catalyze the creation of the plated-through hole.

Electroless plating

A layer of chemical copper will be deposited on the surface of the board or the wall of the hole.

We specialise in designing and manufacturing NADCAP-approved surface finishing plants for a range of chemical processes:

Anodizing

Hard Chrome Plating

Zinc/Nickel Plating

Cadmium Plating

Electroless Nickel Plating

Passivation

Types of Plants

Rack Plant

Types of Plants

Barrel Plant

Types of Plants

Rack-Barrel Combination